About Nanya

Wuxi Nanya Technology Co., Ltd., founded in 1996, is a high-tech enterprise integrating R&D, manufacturing and sales. It is located on the beautiful shore of the Taihu Lake Lake.

DetailNews

Wuxi Nanya Technology Co., Ltd., founded in 1996, is a high-tech enterprise integrating R&D, manufacturing and sales. It is located on the beautiful shore of the Taihu Lake Lake.

DetailTalent recruitment

Wuxi Nanya Technology Co., Ltd., founded in 1996, is a high-tech enterprise integrating R&D, manufacturing and sales. It is located on the beautiful shore of the Taihu Lake Lake.

DetailContact Us

Wuxi Nanya Technology Co., Ltd., founded in 1996, is a high-tech enterprise integrating R&D, manufacturing and sales. It is located on the beautiful shore of the Taihu Lake Lake.

DetailProduct Introduction

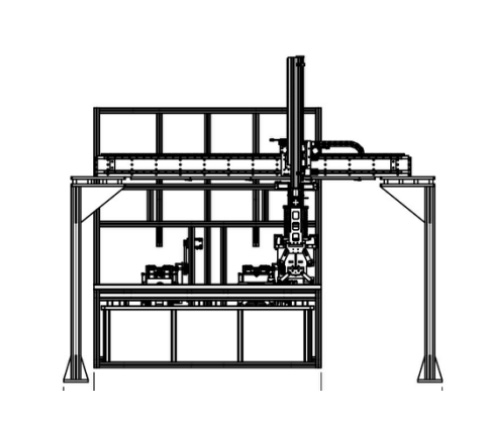

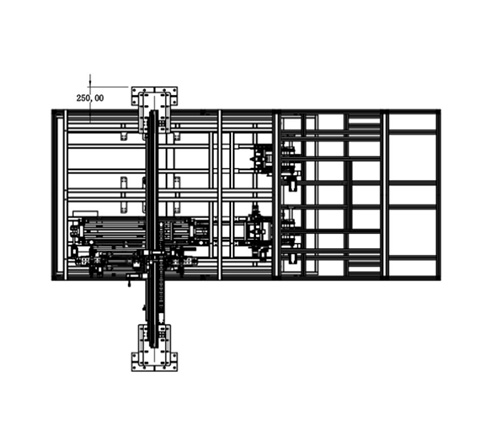

The high capacity continuous fully automatic chip insertion machine is a new type of fully automated equipment independently developed by Nanya company based on the development and market demand of the photovoltaic industry and the international semiconductor industry. On the basis of the patent model of vertical wafer production in South Asia, the entire knife feeding has been achieved by completely changing the silicon wafer feeding method; And it has the function of continuously sending and inserting chips, which can reliably achieve automatic loading through CNC devices, and is equipped with functions such as chain protection, working condition display, and fault alarm.

This equipment is mainly used for automatic packaging of products with similar shapes such as silicon wafers and solar cells before cleaning.

Equipment size: Large capacity continuous chip insertion machine 6500L × 2880W × 2290H(mm)

2) Fragmentation rate: ≤ 2 ‰ (caused by equipment itself, excluding silicon wafer quality issues and other equipment impacts)

3) Edge collapse rate: ≤ 5 ‰ (caused by equipment itself, excluding silicon wafer quality issues and other equipment impacts)

4) Hidden crack rate: ≤ 2 ‰ (caused by equipment itself, excluding silicon wafer quality issues and other equipment impacts)

5) Production capacity: 182mm silicon wafer: ≥ 13000 pieces/hour; 210mm silicon wafer: ≥ 10000 pieces/hour;

6) Suitable for silicon wafers: ① Types of silicon wafers: monocrystalline silicon wafers, polycrystalline silicon wafers

② Silicon wafer size: 182mm ± 0.5mm, 210mm ± 0.5mm, 230mm ± 0.5mm

③ Silicon wafer thickness: 110 μ m ---220 μ m

④ Left and right directionality: matching the operation directionality with the cleaning machine

⑤ Applicable cleaning baskets: 100, 104, 113, 120 Cassette